| Algeria JV Gas Project |  | |||||||||

| PERIMETER PROTECTION FENCING – VEHICLE IMPACT TEST REPORT | |||||||||||

| Purchase review and comments shall not be assumed to indicate either responsibility or liability for the accuracy and completeness of this document or to alter any contractual terms and conditions. | |||||||||||

| Review Code and Status | Signature | Date | |||||||||

| □ | Code 1 | No Comments. Work May Proceed. | |||||||||

| □ | Code 2 | Comments as Noted. Incorporate Comments, Up-Rev. & Resubmit. Work May Proceed. | 28-5-20 | ||||||||

| □ | Code 3 | REJECTED. Incorporate Comments, Up-Rev. & Resubmit. Work May NOT Proceed. | |||||||||

| □ | Code 4 | For Information Only. | |||||||||

| □ | Code 5 | Document Required Cancelled. | |||||||||

| 02 | Test report amended | 02 July 2020 | Ms Paddy | ||||||||

| 01 | submit for review | 05-May-2020 | Ms Paddy | ||||||||

| Rev. | Reason for Issue | Date | Prepared By | Checked By | Approved By | ||||||

| Supplier Name: | JOESCO HEBEI METAL PRODUCTSINC | PO. No. | SO84-1866U-01 | ||||||||

| Package Description: | PERIMETER PROTECTION FENCING | ||||||||||

| Call Off Number: | SO84GD | MoC No. | 1866U | ||||||||

| Supplier Document Number: | JS12 | Rev. | 02 | ||||||||

| Project Document Number: | S0841866U01-K99-0001 | ||||||||||

| Also includes SDRL code(s): | K99-0001 | ||||||||||

Disclaimer: This document has been prepared and developed by Kellogg Brown & Root Limited (KBR) under contract with Sonatrach-S.P.A, BP Exploratioi (El Djazair) Limited, BP Amoco Exploration (In Salah Gas & In Amenas) Limited, Equinor In Amenas AS, Equinor In Salah AS. The contract sets forth the parties’ rights, obligations, and liabilities concerning the content and use of the document. THIS DOCUMENT CONTAINS THE CONFIDENTIAL INFORMATION OF OPERATOR. Therefore it must not be otherwise copied, loaned, or transferred nor must the information it contains be disclosed to any third party except as by the contract. Except as set out in the contract, KBR makes no warranty or representation, express or implied, concerning the accuracy, completeness, timeliness, sufficiency, or fitness of purpose of the information contained in this document and assumes no liability concerning any party’s use of or damages resulting from such reliance or use.

VEHICLE IMPACT TEST REPORT

REVISION HISTORY

| Date | Revision | Detailed Description of Change | Ref. Section |

| 05 May 2020 | 01 | Submit for review | |

| 02 July 2020 | 02 | Statement tables added in section results & section evaluation as per KBR request | 5.8 & 6 |

HOLD RECORD

| Hold Ref. | Description / Reason for Hold | Ref. Section |

| Hold 1 | ||

| Hold2 | ||

| Hold 3 | ||

| Hold 4 |

Hold4

TEST REPORT FOR CRASH BARRIER

Commodity Name: JOESCO QSVI Perimeter Protection Fencing Client: JOESCO Hebei Metal Products Inc.

Test Type: Commission Test

Reference Standard: F2656/F2656M-15

Test Date: 18 April, 2020

Report Number:202001015

Approval Date:28 April, 2020

Official test report language: English

Contents

- IDENTIFICATION 3

- BARRIERS DESCRIPTION 4

- Barriers Model: QSVI 4

- Barriers Drawing 4

- Installation and detailed description of test item 5

- Photographs of the Barriers 5

- TEST VEHICLE 7

- TEST PROCEDURE 10

- RESULTS 12

- EVALUATION 17

- POST-TEST VEHICLE DESCRIPTION 18

- POST-TEST BARRIER DESCRIPTION 19

- GENERAL STATEMENT 21

- APPROVAL OF REPORT 21

APPENDIX THE MAIN PARTS OF THE DRAWING 22

- Identification

- Test laboratory

Name: Beijing Shenhuada Traffic Engineering Test Co., Ltd.

Address: BaiYangChengVillage, LiuCunTown, Changping District, Beijing, China,

Telephone number: (8610) 69780662

Facsimile number: (8610) 69780662

Test site location: Testing Laboratory of ShenhuadaTraffic Engineering Test Co., Ltd. in Changping

District, Beijing.

Registration No.CNAS L0957(Date of Expiry:21 March, 2024)

Additional information: None

- Client

Name: JOESCO Hebei Metal Proudcts Inc.

Address: Plant 5 No. 612 Zhangshe Village Beixiang, Anping County, Hengshui, China

Telephone number:+8613903287878

Facsimile Number: +86031187733508

Internet website: www.militarybarrier.com

Additional information: None

- Test item

Name of test item: Perimeter Protection fencing Vehicle Impact Test

Test type: Commission

Test reference standard: F2656/F2656M-15

Condition designation: C740

Test reference number: HBSIII-2020-01

Date of installation: 16 April, 2020

Date of test: 18 April, 2020

- Barriers Description

- Barriers Model: QSVI

- Barriers Drawing

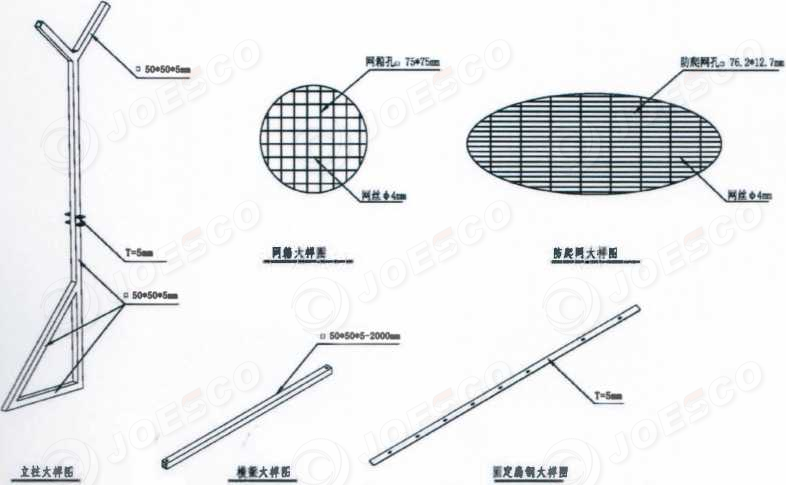

Drawing enclosures are shown in Figure 1.

- Installation and detailed description of test item

Conformity between test item drawings and item tested: Yes (P) No ()

Conformity between installation manual and item installed: Yes (.) No ()

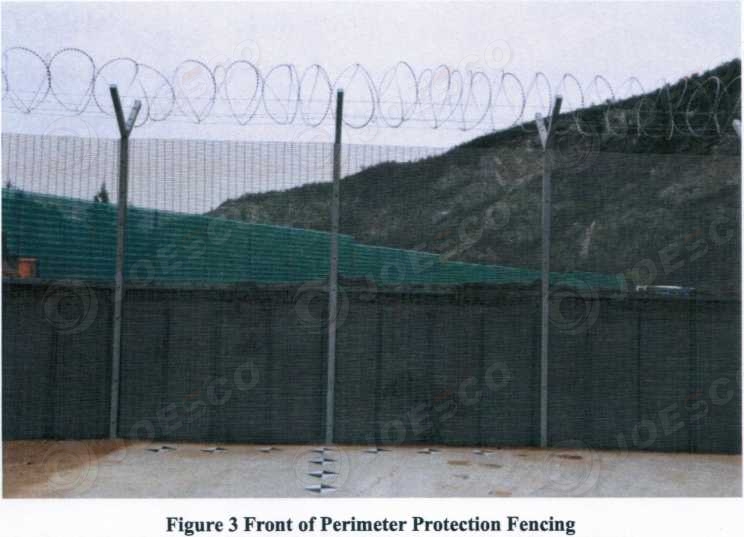

The Length of JOESCO Perimeter Protection Fencing installed for the Impact test was 42.40m. It consisted of 20 sections, each with a length of 2.12m. The Perimeter Protection Fence was positioned on the test site to ensure the middle point was aligned with the middle point of the vehicle impact test. The perimeter protection fencing is an anti-climb galvanized mesh fence supported by metal columns and reinforced with a modular unit.

Length of barrier installed in meters: 42.40m

The height of the Perimeter Protection Fencing (from the top line of the Perimeter Protection Fencing section to ground level) is 3.00m.

The width of Perimeter Protection Fencing is 1.06m.

Impact point: The middle point of Perimeter Protection Fencing.

The Perimeter Protection Fencing No anchorage and fixation

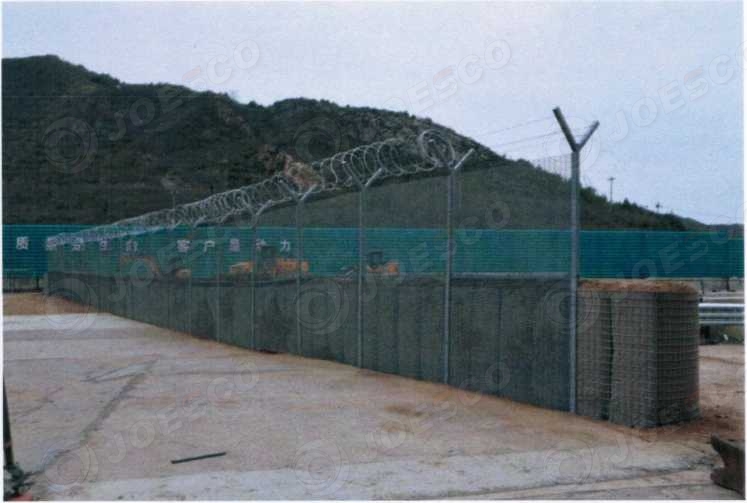

Photographs of the Barriers

Figure 2 Overall of Perimeter Protection Fencing

Test Vehicle

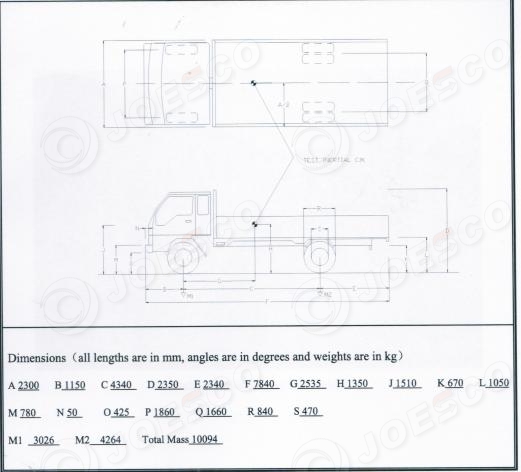

Model: WUZHENG

Model year: Unknown

Vehicle identification number (VIN): Unknown

Engine displacement: Unknown

Transmission type: Manual

Tire pressure: 0.8MPa

Mass of the vehicle in kilograms: 4216 kg

Ballast mass in kilograms:3074 kg (as shown in figure 5)

(The Ballast was prefabricated from concrete and tightly welded in the compartment of the Vehicle)

Total test mass in kilograms:7290 kg

Dimensions, characteristics, and position of the center of gravity of test vehicle:

Table 1 Vehicle details

Photographs of Test Vehicle

Figure 5 The Ballast

Figure 6 Rear view of the test vehicle

Figure 6 Rear view of the test vehicle

Figure 7 Side view of the test vehicle

Test procedure

Impact Condition

Condition Designation: C740

test velocity in kilometers per hour: 65km/h

Target impact angle in degrees: 90.0°

Test Inertial Vehicle in kilograms: 7200kg

Test area

Figure 8 Overview of the test site

Test Sequence

- Construction of test site and Crash Perimeter Protection Fencing

- Installing instrumentations and setting cameras

- Tow the vehicle to the designated position

- Start full-scale impact test and collect data

- Analysing Data and Producing Report

Instrumentation

List of test instruments

| No. | Name | quantity | Specification | Date of Expiry |

| 1 | Photoelectric velocimeter | 1 | E3Z-T61A | 2020.12.03 |

| 2 | Tape measure | 1 | 10m | 2020.12.22 |

| 3 | Tape measure | 1 | HTN-50 | 2020.12.30 |

| 4 | Acceleration collector | 1 | 7264C-2K+SPC-01 | 2020.07.28 |

| 5 | Accelerometer | 4 | 64C-2000-360-011 | 2020.07.28 |

| 6 | High- speed digital video camera | 2 | UX-50/Photron SA3-60K | / |

| 7 | video camera | 6 | SONY HDR-CX680 | / |

| 8 | Digital camera | 1 | Nikon-D750 | / |

Table 2 List of test instruments

Accelerometers

Accelerometers have been mounted to collect accelerations of the vehicle during impact

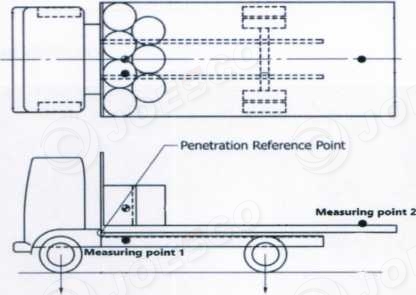

tests. The illustrations are detailed in Table 2 and Figure 9.

| No. | Installation position | direction | Accelerometer No. | Date of Expiry |

| Measuring point 1 | On the longitudinal beam below the center of mass | longitudinal | A301783 | 2020.07.28 |

| lateral | A301785 | 2020.07.28 | ||

| Measuring point 2 | On the rear floor of the longitudinal axis of the Cargo compartment | longitudinal | A301786 | 2020.07.28 |

| lateral | A301787 | 2020.07.28 |

Table 3 Accelerometer layout

- Center of Mass

- Accelerometer

Figure 9 Accelerometer layout

- Results

5.1 Environment condition

Date and Time: 5:42 PM, April 18, 2020

Weather conditions at test: sunny

Temperature:14°C

Humidity: 42%RH

Wind speed: O.lm/s

- Test Item

| Condition Designation | C740 | |||

| No. | Item | test result | ||

| 1 | Test Inertial Vehicle | 7290 kg | ||

| 2 | test velocity | 65.7 km/h | ||

| 3 | impact angle | 89.7° | ||

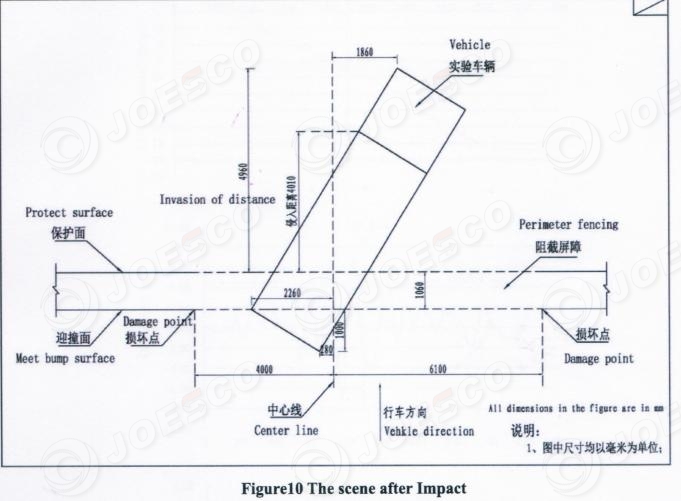

| 4 | Barrier damage | damaged by 10.1m(left 4.0m/right6.1m) | ||

| 5 | Vehicle damage | disabled | ||

| 6 | Final resting point | 6.0m | ||

| 7 | Dynamic Penetration distance | 4.0m | ||

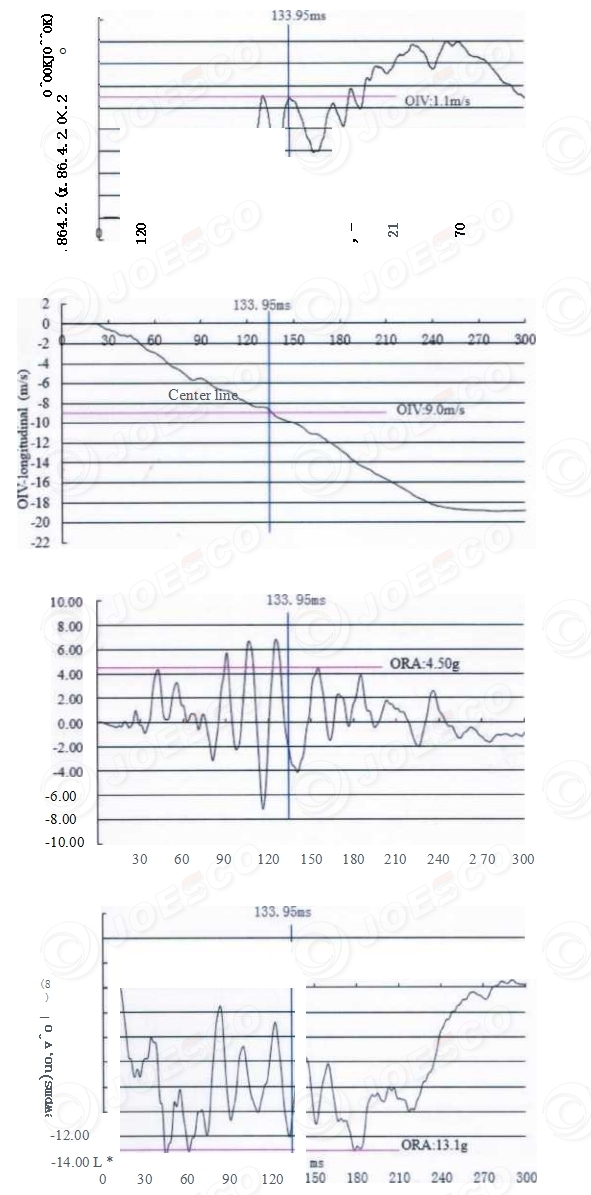

| 8 | Measuring point 1 | occupant impact velocity | lateral | 1.1 m/s |

| longitudinal | 9.0 m/s | |||

| Ride down Acceleration | lateral | 4.5g | ||

| longitudinal | 13.1g | |||

| Measuring point 2 | occupant impact velocity | lateral | 1.3m/s | |

| longitudinal | 8.4 m/s | |||

| Ride down Acceleration | lateral | 4.6g | ||

| longitudinal | 13.1g | |||

5.3 Dynamic Penetration Distance

5.4 Final resting point

5.5 The scene after Impact

5.6 Acceleration

5.6.1 Measuring Point 1

5.6.2 Measuring Point 2

5.7 Impact procedure

5.7.1 Perpendicular High-speed Digital Video Camera View

5.7.2 Overhead High-speed Digital Video Camera View

5.8: Statement of result JOESCO QSVI Impact Test

| Vehicle retained | YES |

| Vehicle immobilized | YES |

| QSVI remains functions after impact | YES |

| Penetrating rating | P2 ( 4m) |

| ASTM F2656/F2656M-15 C740 P2 | PASSED |

Evaluation

| NO. | Performance | |

| 1 | Barrier damage | damaged by 10.1 m(left 4.0m/right6.1 m) |

| 2 | Vehicle damage | disabled |

| 3 | Final resting point | 6.0m |

| 4 | Dynamic Penetration distance | 4.0m |

| CONCLUSION | ASTM F2656/F2656M-15 C740 P2 | PASSED |

Post-test Vehicle Description

After impact, The front bumper, headlight, windshield, and front axle of the impact vehicle were damaged, the vehicle’s cab was severely squeezed and deformed, and the vehicle was disabled.

Figures 11 to 13 below show the damages on the test vehicle after impact.

Figure 11 Front view of the damaged test vehicle

Figure 12 Reverse right view of the damaged test vehicle

Figure 13 Serious damage to test vehicle

Post-test Barrier Description

After impact, the left Perimeter Protection Fencing of the vehicle driving center line is damaged by 4m, and the Perimeter Protection Fencing barriers are damaged by 6.1m。

The test vehicle remained in the Perimeter Protection Fencing after impact and access for a secondary vehicle to drive through was blocked.

Figures 14 to 16 show the damages on Perimeter Protection Fencing which are resulting from the Impact.

Figure 14 Front view of Perimeter Protection Fencing after impact

Figure 15 Deformation of test Perimeter Protection Fencing

Figure l6 Scratch marks of Perimeter Protection Fencing

- General Statement.

- The test results in this report relate only to the VRS tested.

- This report is invalid without a special directional seal and connective seal.

- This report is invalid without a signature from the Technical Manager.

- This report shall be free from any alteration, and shall not be reproduced other than in full, except with the prior written approval of the issuing laboratory.

- The test results in this report relate only to the items tested.

- Please raise any objection within thirty days of the submission of the report.

Appendix The main parts of the drawing